Autonomous Farm Vehicles: Which Manufacturer is Leading the Race?

Over the years, we’ve witnessed an acceleration in the development of autonomous farming solutions across the world. From robotic harvesters to drones that monitor crop health, the AgriTech sector is undergoing a seismic shift.

The ever-evolving world of AgriTech has reached new heights and is frenzied with the race to develop autonomous farm vehicles. Autonomous farm vehicles are becoming increasingly sophisticated and capable, and are ready to revolutionize the agricultural industry. These vehicles can perform a wide range of tasks, from planting and harvesting to weeding and spraying, with little or no human intervention.

While the mechanical engineering aspects of creating these machines may seem straightforward – choosing the right powertrain, deciding between tracks and wheels, and building a suitable chassis – the real challenge lies in integrating advanced sensors, cameras, Lidar, satellite guidance, and other technologies that can withstand the rugged conditions of farmwork. The true heroes of this revolution are the software writers and electronics engineers who bring it all together, creating a digital platform for planning tasks and enabling 24/7 remote monitoring via mobile devices.

One of the biggest challenges in developing autonomous farm vehicles is creating a system that can reliably navigate complex environments and avoid obstacles. This requires a combination of sensors, cameras, and artificial intelligence.

Another challenge is to develop a system that can efficiently and accurately perform agricultural tasks. This requires a deep understanding of the specific task at hand, as well as the ability to adapt to changing conditions.

Despite the challenges, there has been significant progress in the development of autonomous farm vehicles in recent years.

These autonomous machines are addressing two critical issues in agriculture: the scarcity of skilled operators and the imperative to protect soils through the use of smaller, lighter machinery that can work longer hours. A number of companies are now offering commercial products, and many more are in development. Let’s delve into some remarkable innovations in the field.

AgXeed AgBot

Where innovation reigns supreme, the AgXeed AgBot stands as a testament to the boundless potential of autonomous farming. This remarkable range of purpose-built autonomous tractors is revolutionizing agriculture, offering a spectrum of capabilities that cater to the diverse needs of modern farming.

At the helm of the AgBot lineup is a 156hp twin-track machine, a powerhouse designed to tackle the most demanding agricultural tasks. Complementing this titan are the 75hp four-wheel drive and narrow trike models, ensuring that there’s an AgBot for every application on the farm.

What unites these autonomous marvels is their innovative Deutz diesel-electric power unit. This ingenious setup sees the engine driving an integrated generator that supplies power to electric motors, a technological marvel in itself. Furthermore, these AgBots offer the option to incorporate a 55kW (74hp) electrically driven power take-off (PTO) at the rear. What sets this PTO apart is its ability to rotate both clockwise and anti-clockwise, affording these vehicles the unique capability to work with PTO-driven implements in either direction, with the implement leading or trailing.

The tracked AgBot 5.115T2 is a testament to engineering excellence. It boasts a substantial 350-litre fuel capacity, ensuring extended hours of uninterrupted operation. Additionally, it features up to four double-acting proportional spool valves, along with an 85-litre/min hydraulic pump that can be upgraded to a load-sensing system. This combination of power and hydraulic efficiency empowers the AgBot to seamlessly handle a diverse range of tasks.

Implement carriage is a crucial aspect of any agricultural machinery, and the AgBot shines in this regard. It sports an 8-tonne capacity three-point linkage at the rear, complemented by a 3-tonne capacity assembly at the front. This design flexibility allows for the transportation of various implements, such as a rear-mounted drill with a hopper.

One of the defining features of the AgBot range is its adaptability to different crop and cropping systems. With numerous combinations of traction belt widths, ranging from 300mm to 910mm, and adjustable track spacings, these autonomous workhorses can effortlessly navigate varying agricultural terrains.

The AgBot 2.055W3, often referred to as the “trike,” is tailored primarily for orchard and vineyard applications. Its versatility shines through as it can be configured to be as narrow as 1.38 meters, ensuring easy navigation through tight spaces.

On the other hand, the four-wheel AgBot 2.055W4 offers a more versatile autonomous solution, catering to farming and commercial horticulture. With front-end steering, unequal tire diameters, and tire widths typically ranging from 270mm to 710mm, this model provides a robust and adaptable solution for various agricultural needs. Its hydraulics setup mirrors that of the tracked machine, featuring up to three spools and implement linkage capacities of 1.5 tonnes at the front and 4 tonnes at the rear.

The AgXeed AgBot range exemplifies the evolving landscape of agricultural technology, where automation and innovation converge to redefine farming as we know it. These autonomous tractors are not just machines; they are the future of agriculture, providing efficiency, precision, and adaptability that empower farmers to meet the demands of a changing world.

CNH Industrial

CNH Industrial, the parent company of Case IH and New Holland has a rich history of innovation and a commitment is pushing the boundaries of agricultural technology by easing into commercial autonomous tech after successful exploratory projects that hinted at a future where machines take the reins in the field.

One of their pioneering ventures, the Case IH AVC concept, introduced the idea of a cabless Magnum tractor, a bold step that showcased the potential of autonomous farming machinery. Following this trailblazing concept, CNH Industrial unveiled the New Holland NHDrive T8, a driver-optional tractor with autonomous working capabilities. These projects laid the groundwork for what was to come.

Fast forward to 2023, and CNH Industrial has set its sights on revolutionizing agriculture in the United States with the introduction of the Case IH Farmall 75C Electric and New Holland T4 Electric Power utility tractors. These battery electric tractors herald a new era, with limited self-driving features that promise to reshape the farming landscape.

One standout feature of these electric tractors is the “Follow Me” function. It allows operators to effortlessly guide the tractor along a designated path, such as a feed or fence line, without the need to constantly climb in and out of the cab. By simply walking ahead of the tractor and transmitting the appropriate commands through a smartphone app, the operator can ensure precise and efficient navigation. No more need for manual intervention during these routine tasks.

Another game-changing function empowers the tractor to autonomously pass-through gateways under remote command. This means no more time wasted hopping on and off the tractor to open and close gates, a common task that has traditionally disrupted workflow on the farm. With this innovation, the tractor seamlessly adapts to its environment, enhancing efficiency and reducing operator fatigue.

Agrointelli Robotti

This Danish manufacturer’s Robotti tool-carrier is a versatile workhorse capable of operating various implements. Its capabilities are nothing short of astonishing, and it’s a testament to the ongoing transformation in agricultural technology. It has demonstrated its prowess by sowing beans, oilseed rape, cereals, sugar beets, maize, vegetables, salad crops, weeding, and even planting potatoes, showcasing its adaptability to diverse farming needs.

This intelligent machine represents a pivotal leap towards a more efficient and sustainable future for agriculture, effortlessly handling a wide array of implements between its four wheels.

But what truly sets the Robotti apart are its two distinctive versions, each tailored to meet specific agricultural demands. The Robotti LR is designed for light-duty operations, equipped with a modest 750k-rated linkage assembly. Its power source is a single 72hp Kubota diesel engine, ensuring up to 60 hours of uninterrupted operation on a single tank of fuel.

In contrast, the 150D version steps up to 144hp, making it suitable for more demanding tasks. It boasts an impressive 1,250kg lift capacity, a power take-off (PTO) system to drive various implements, and the brilliance of two engines – one for propulsion and another for PTO and hydraulic functions. This dual-engine setup provides a formidable total power output of 144hp when the situation demands it.

The Robotti’s design is a marvel of engineering, with a short wheelbase measuring a mere 1.55 meters. It offers flexibility with track widths ranging from 1.8 meters to 3.65 meters, making it adaptable to varying crop and terrain conditions. Its standard 320/65 R16 tires provide stability, while an optional narrower 260/70 R16 configuration is available for specific needs.

Maneuverability is at the heart of the Robotti’s operation, thanks to its front-end steering and four-wheel drive system. When being manually controlled, it can achieve speeds of up to 10 kilometers per hour, ensuring precise navigation. During work, the Robotti gracefully halves its speed, maintaining the utmost accuracy in steering.

Combined Powers

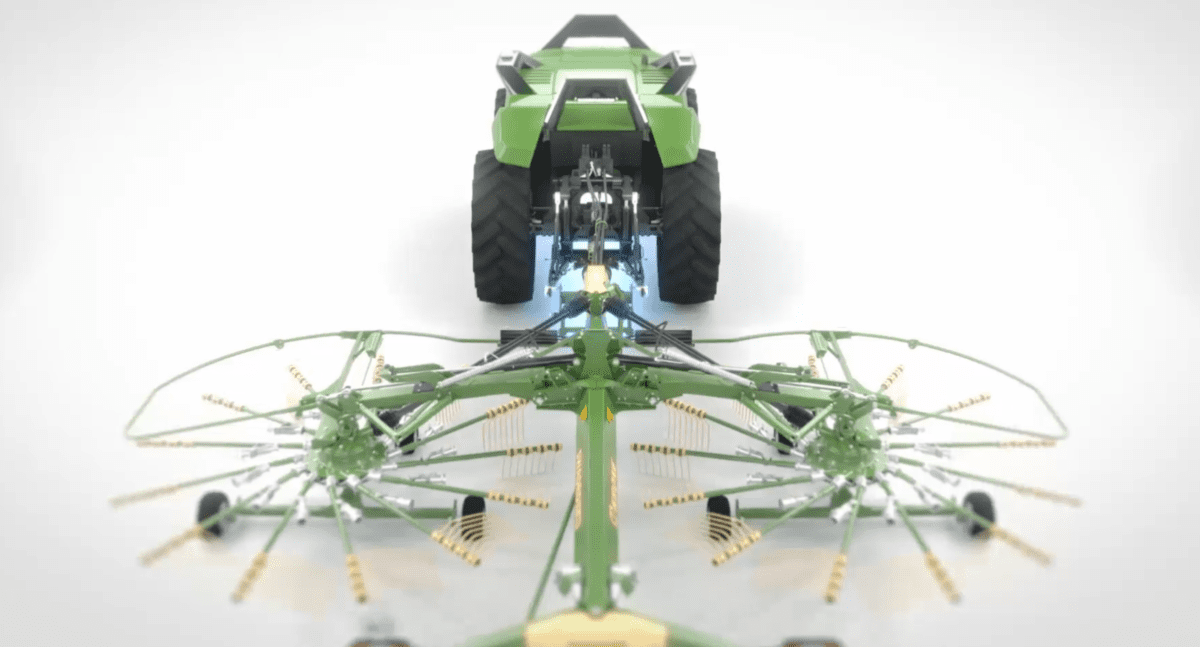

In a groundbreaking collaboration that fuses the expertise of grassland equipment specialist Krone and tillage machinery firm Lemken, a remarkable stride in agricultural technology has emerged—a four-wheel-drive tractor designed exclusively for autonomous operation. This revelation represents the pinnacle of innovation in the ever-evolving AgriTech industry and aligns seamlessly with the transformative momentum we’ve observed over the years.

With dimensions measuring 2.7 meters in width and a modest height of 2.6 meters, this autonomous marvel tips the scales at a sturdy 7.5 to 8 tons. Powered by a diesel-electric unit delivering an impressive 170kW (230hp), this tractor is more than capable of executing a wide array of tasks, from ploughing, cultivating, and seeding to mowing, tedding, and raking. Its versatility knows no bounds.

What sets this tractor apart is its intricate control system, tailored to harness the power of isobus Tractor Implement Management (TIM). This cutting-edge integration enables seamless communication between sensors and a dedicated job computer on the implement and the tractor itself. This means that control instructions, ranging from speed adjustments to hydraulic tweaks, and even start-stop commands, can be relayed effortlessly.

The year 2022 marked a significant milestone when this autonomous wonder publicly demonstrated its field capabilities. However, the journey doesn’t stop there. The project is now embarking on a phase of rigorous testing, exposing the tractor to typical and extreme working conditions. Simultaneously, invaluable feedback is being collected from farmers and contractors, providing essential insights into the concept’s practicality and adaptability.

John Deere

As a pioneer in the industry, John Deere continues to push the boundaries of innovation with its groundbreaking forays into autonomous technologies and vehicles.

One of the most exciting breakthroughs from John Deere is the guided tractor and sprayer designed for orchards and similar applications. These intelligent machines feature automatic re-filling capabilities, enhancing efficiency and reducing the need for constant operator oversight.

John Deere has also unveiled a purpose-built driverless sprayer, specifically configured for high-clearance maize spraying, utilizing four track units for superior maneuverability. This innovation caters to the specialized needs of various crops, showcasing the adaptability of autonomous technology in the agricultural sector.

Recently, we have observed how the AgriTech industry worldwide has embraced electric-powered machinery. John Deere has not lagged behind in this aspect, introducing a remarkable 500kW (670hp) electric-drive single-axle autonomous tractor. This versatile tractor can seamlessly transition between wheels and tracks when coupled with cultivators, drills, and similar implements. This development resonates with the global shift towards sustainable and eco-friendly farming practices.

However, the revelation that truly turned heads was John Deere’s announcement in January 2022 regarding the imminent release of an autonomous version of its revered 8R series tractor in the USA. While the order book remains closed for now, the anticipation is palpable. The initial focus for this autonomous marvel will be chisel cultivation work, featuring the most potent model in the 8R series lineup.

The 8R 410, boasting 443hp for draft work and 458hp for PTO, transport, and applications with intense hydraulic demands, maintains the familiar configuration of its conventional counterpart. Still, it incorporates a groundbreaking feature—an array of six pairs of stereo cameras that facilitate 360-degree obstacle detection and distance calculation.

FarmDroid

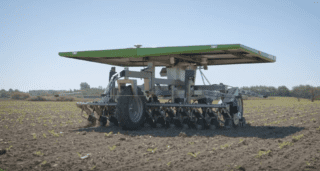

FarmDroid’s FD20 stands out as a specialist tool carrier dedicated to precision sowing and weeding. Operating predominantly in the United Kingdom, it is finding its niche in organic sugar beet, fodder beet, and vegetable production.

The FarmDroid FD20, available in both trike and four-wheel configurations, showcases a commitment to sustainable energy sources. This marvel of engineering harnesses battery-electric power, fortified by an expansive solar panel canopy. But what truly sets it apart are the two unique autonomous power unit concepts currently being explored by Horsch, a pioneer in agricultural technology.

One concept takes the form of a driverless tracked unit that bears a striking resemblance to the traditional field tractor. The other, a formidable large tool carrier-type machine, is no less impressive. While official specifications remain somewhat elusive, insiders suggest that the Robo independent power unit, despite its compact size, boasts a formidable 450hp diesel engine. Equipped with either a hydrostatic drive or a hydro-mechanical “vario” transmission, it offers remarkable versatility.

The Robo’s ingenuity extends to its remote manual control for easy setup and a convenient pull-out drawbar at the front, allowing effortless towing to and from the field. But it’s the field trials featuring the Robo operating a trailed Maestro precision planter in a close-coupled configuration that have truly turned heads. This configuration effectively transforms the Robo into a self-propelled outfit, with the tracked unit shouldering a significant portion of the seed cart’s weight, offering efficiency like never before.

Kubota

Kubota, a name synonymous with agricultural machinery, made waves in 2020 when they unveiled the Kubota X, a four-track electric tractor concept that embodied the future of farming. Fast forward to today, and Kubota is on the cusp of turning this vision into reality by testing a fleet of autonomy-capable AgriRobo wheeled tractors.

Japan is facing a unique crisis with an aging population of farmers and a reluctance among younger generations to step into the shoes of their predecessors. This demographic challenge threatens the sustainability of agriculture in the country, but Kubota is determined to find a solution.

In addition to their iconic rice transplanter and rice combine, Kubota has introduced the MR1000A, a 100hp tractor equipped with an impressive array of self-driving guidance and sensor technologies. This innovation aims to ease the farm labor shortage by providing farmers with cutting-edge tools that enhance productivity and reduce their dependence on manual labor.

Horsch

One of Horsch’s visionary projects is the Robo independent power unit. This compact yet formidable machine is shrouded in secrecy, but some intriguing details have emerged. At its heart, it boasts a robust 450hp diesel engine, coupled with either hydrostatic drive or a hydro-mechanical “vario” transmission. This powerful combination ensures that the Robo is more than capable of tackling the demands of modern agriculture.

What sets the Robo apart is its versatility. With remote manual control for setup and a front-mounted drawbar, it can be effortlessly towed to and from the field, making it as adaptable as it is powerful. In a fascinating twist, the Robo has been put through its paces in field trials, where it operated in conjunction with a trailed Maestro precision planter. This close-coupled configuration effectively transforms the Robo into a self-propelled unit, with the tracked platform bearing the weight of the seed cart.

Meanwhile, Horsch’s Brazilian division is making waves with a gantry-like machine designed for precision planting. This 24-meter Maestro precision planter, tailored for maize, is perched atop four large-diameter swivel-steer drive wheels with hydrostatic propulsion motors. The design’s wide frame, which transitions seamlessly from the yard to the field, houses a central power unit flanked by hoppers on either side, with planter units suspended beneath.

While these innovations are undeniably impressive, what’s even more intriguing is the potential for a commercial rollout. Horsch has been collaborating with Trimble to develop an autonomy package for self-propelled sprayers. This partnership extends beyond just autonomous control; it encompasses full workflow automation, bridging the gap between office and field.

In its initial phase, the collaboration aims to automate planning, machine control, and logistics for sprayer operators. This holistic approach not only enhances machine performance but also alleviates the operator’s workload and minimizes the risk of errors. It’s a significant step towards realizing fully autonomous agricultural machines.

Raven Industries

One of Raven’s groundbreaking contributions to the field is the development of two systems tailored to enhance the productivity of US growers. First in line is the OmniDrive system, a marvel of technology that empowers combine operators to effortlessly synchronize with automated grain tractors and trailers. This synchronization feature not only streamlines operations but also alleviates the burden on farmers during the demanding harvest season. This concept isn’t entirely new in the AgriTech world, as it builds on the foundation laid by similar systems globally.

The second jewel in Raven’s crown is the Cart Automation system. Unlike OmniDrive, this system focuses solely on speed and heading synchronization. Its beauty lies in its versatility, as it can be retrofitted to virtually any make of machinery and adapted to various harvesting tasks, including sugar beet farming. This adaptability showcases Raven’s commitment to providing solutions that cater to a wide spectrum of agricultural needs.

Raven Industries hasn’t limited its innovation to retrofit solutions alone. In a significant stride towards full autonomy, they have recently unveiled a comprehensive solution for the Case IH Trident 5550 self-propelled fertilizer spreader. This development resonates with the global trend of automating agricultural equipment, as we’ve seen similar strides in precision farming systems across continents.

While Raven’s Autonomy division primarily focuses on electronics and software, they do have a vehicle in their portfolio—the OmniPower 3200 tool carrier. Originally developed in collaboration with Dot Technology and Seedmaster in Canada, this vehicle boasts hydrostatic drive, four-wheel steering, and interchangeable modules for sowing, spreading, and spraying. It’s a testament to Raven’s commitment to diversification and ensuring they offer comprehensive solutions to their clientele.

To sum it up, we have seen that in this era of technological advancement, the agriculture technology industry is witnessing a transformation that promises increased efficiency, reduced labor dependency, and enhanced sustainability. These autonomous farm vehicles are not just a glimpse into the future of agriculture; they are the future, working tirelessly to meet the demands of modern farming while protecting our precious soils. As we look back on the journey so far, it’s clear that the AgriTech industry is on an unstoppable trajectory towards smarter, more sustainable agriculture.